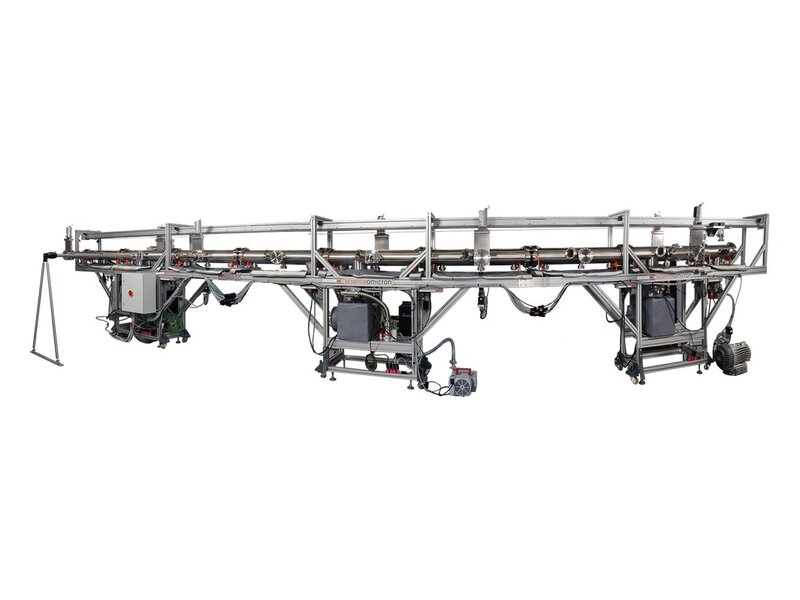

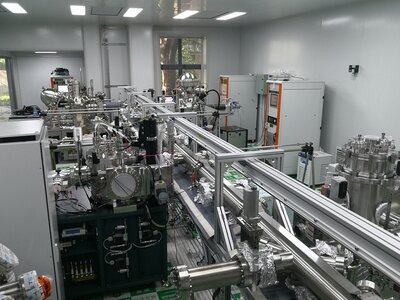

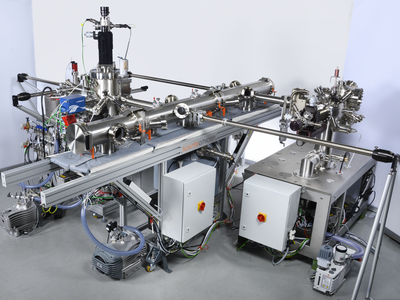

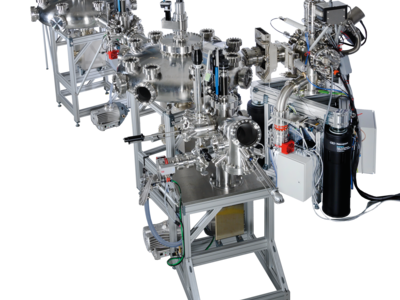

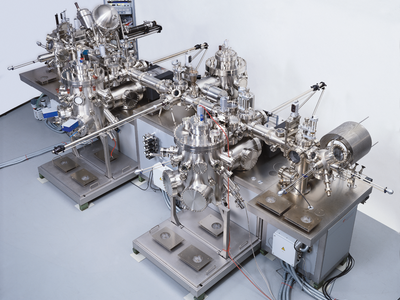

Linear Transfer Line (LTL)

A Versatile Backbone for UHV Cluster Systems

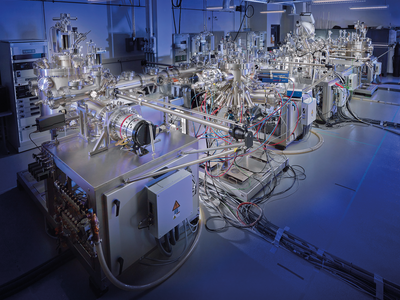

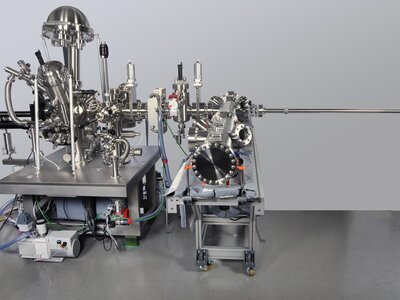

- Convenient sample transfer under true UHV conditions

- Robust magnetic coupling between external driver and in-UHV sample trolley maintains connection as the trolley passes through flange connections and gate valves

- Sample trolley accepts multiple sample plates or wafer carrier rings

- Samples and even the whole trolley are easily exchanged via the load lock segment

- No length restrictions

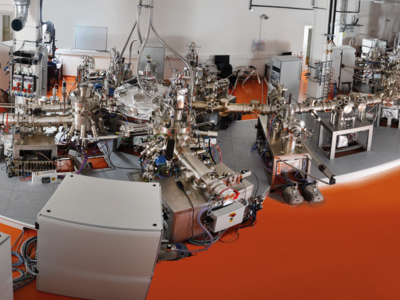

- Designed for future expandability, also in combination with Rotary Distribution Chambers (RDC)

The Linear Transfer Line (LTL) is a backbone for reliable and convenient sample handling in large UHV systems. Its modular design allows for cost-effective individual configurations, particularly of its length, the pumping system and the sample plates or wafers used. The LTL is easy to extend with additional segments to allow users to extend their UHV cluster step-by-step.

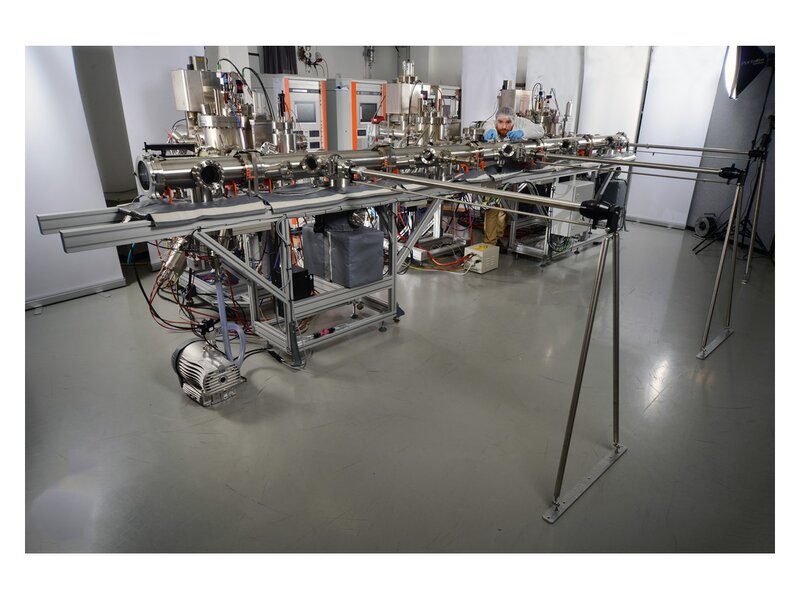

The newly developed Linear Transfer Line (LTL) efficiently connects new and existing growth and analysis modules for Materials Innovation Platforms. The transfer is composed of independent, movable 3 m long segments and therefore removes length restrictions and provides for cost-effective expandability.

Optimised pumping and quality design ensure true UHV conditions while providing a high degree of configuration flexibility. Gate valves can be used to separate LTL sections, minimising cross-contamination and isolating subsystems for servicing. Multiple LTLs can easily be integrated with rotary distribution chambers.

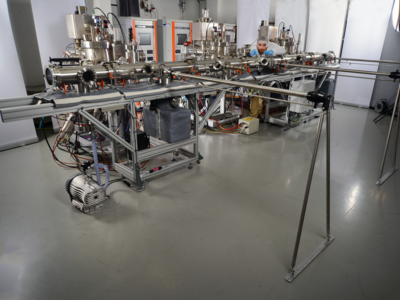

The trolley is moved either manually or with an optional stepper motorisation. If the latter is chosen, the MISTRAL system control is provided installed on a tablet PC to ensure maximum flexibility and convenience while the users navigate their samples through the cluster system.

More Information

Linear Transfer Line (LTL): Transfer Backbone

This video shows how the newly designed Linear Transfer Line (LTL) functions and explains how it removes length restrictions, providing for cost-effective, high quality expandability. It is composed of independent, moveable 3 m long segments, the LTL efficiently connects new and existing growth and analysis modules, maximising lab space for materials innovation platform (MIP). Furthermore, its optimised pumping and quality design ensures true UHV Conditions while providing a high degree of configuration flexibility.