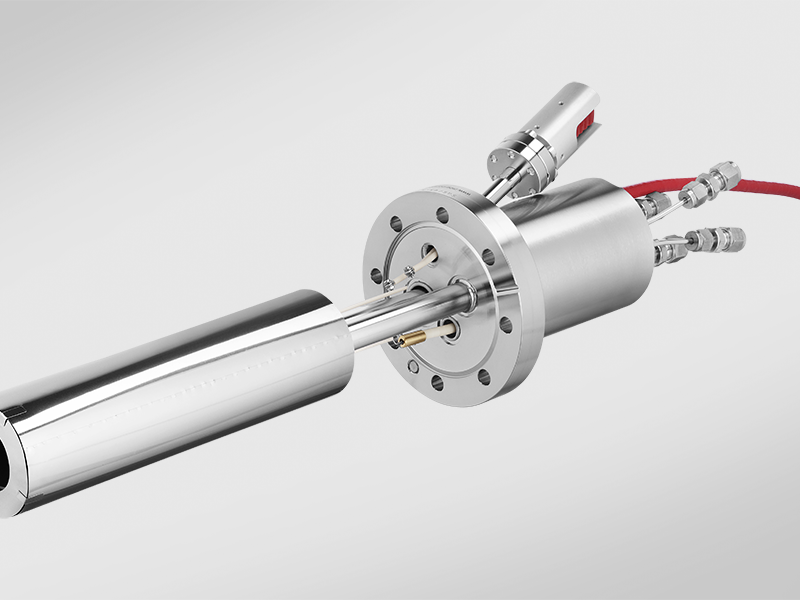

The Silicon Sublimation Source, SUSI, was developed for growing thin Si layers, short period Si/Ge superlattices and Si/SiGe heterostructures. It allows for growth of thin epitaxial Si layers with a crystal quality not otherwise possible by evaporation from effusion cell crucibles. All main parts of the SUSI assembly are made from high purity monocrystalline silicon.

The specially designed free standing silicon filament arch is directly heated by electrical current and is surrounded only by high purity silicon shielding parts.

Extreme heating of metal and ceramic parts is avoided by very effective water cooling of the electrical contacts, and by shielding the hot silicon filament completely with silicon only. No insulating ceramic parts are used in the hot zone.

As the sublimating filament is totally surrounded by Si shielding parts the SUSI provides an extremely clean Si flux. In a well-designed Si MBE chamber a pressure in the 10-10 mbar/torr range is achieved while running the SUSI at maximum growth rate.