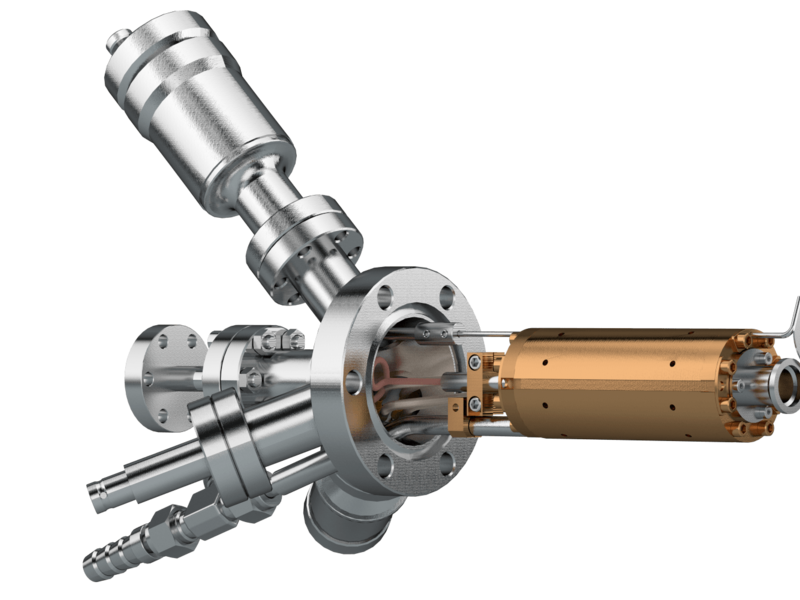

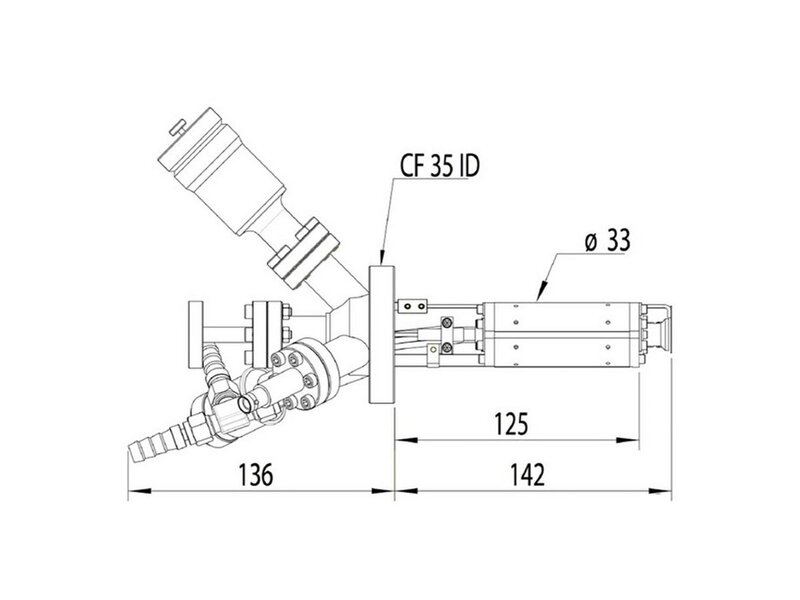

The EFM-H is a source to provide atomic hydrogen based on the design of the EFM 3. A flange NW 16 CF on the rear side is used for molecular hydrogen inlet including a pumping by-pass to clean the piping prior to H2 disposal.

The EFM-H is an ideal instrument for the cleaning and etching of semiconductor surfaces (such as Si, GaAs, Ge or InP), for surface passivation, for improvement of thin film growth and other similar applications using atomic hydrogen.

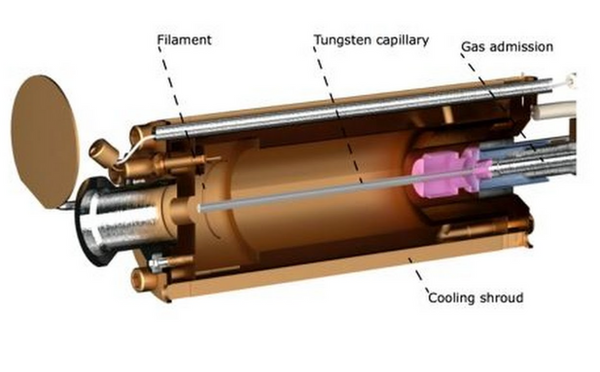

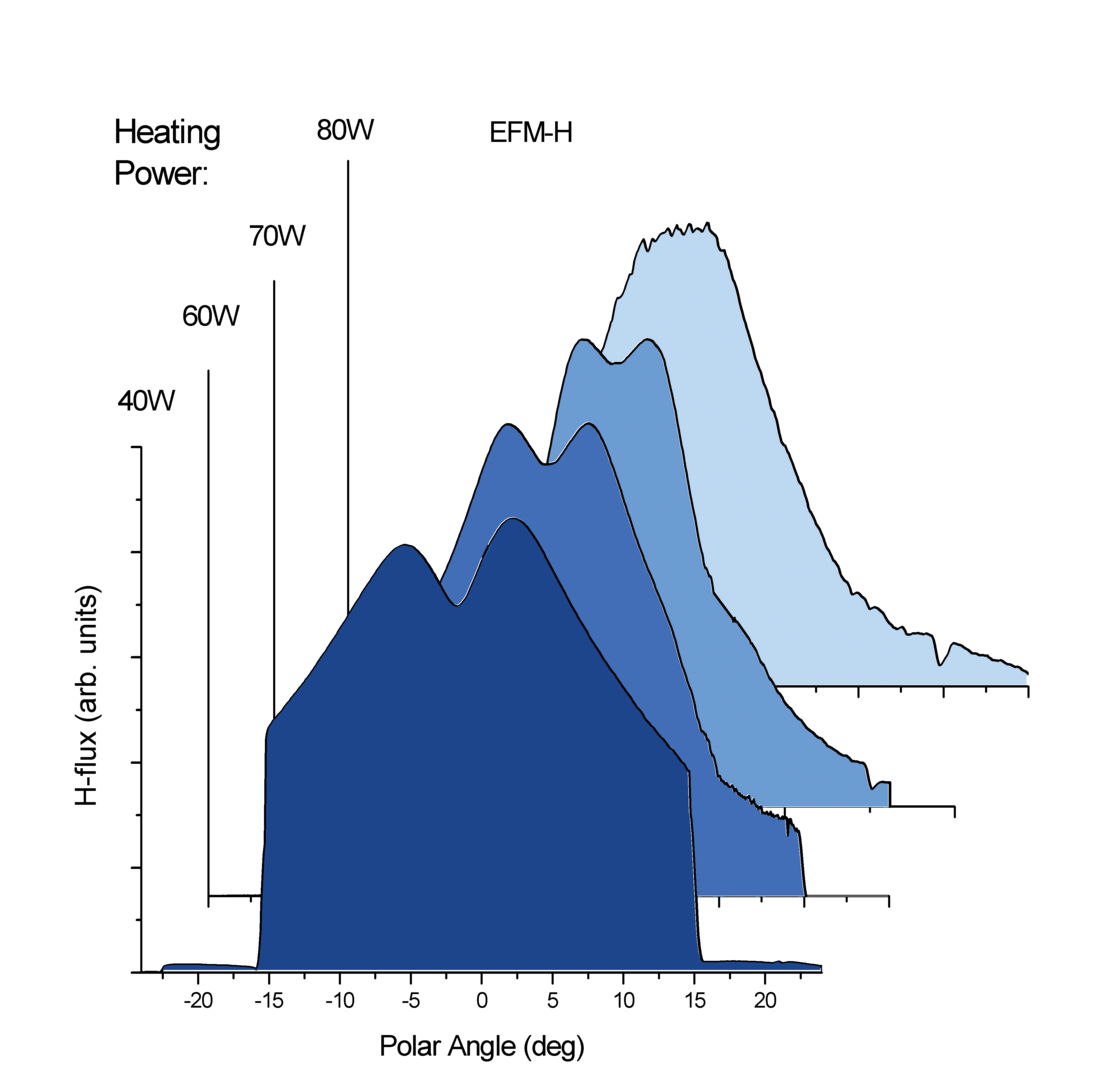

The EFM-H features a cracking efficiency close to 100 %, a smooth, flat and sharply defined spot profile, a low background pressure and a surprisingly low power consumption demonstrating the outstanding performance of the EFM-H. The temperatures, heating power, and other parameters required for the thermal dissociation of H2 molecules at a tungsten surface are very similar to those applied during operation of the well-known EFM evaporator.

The crucible is replaced by a thin tungsten capillary, and Hydrogen is flown through that capillary. The tungsten capillary is then heated by electron beam bombardment.

More Information

Electronics & Software

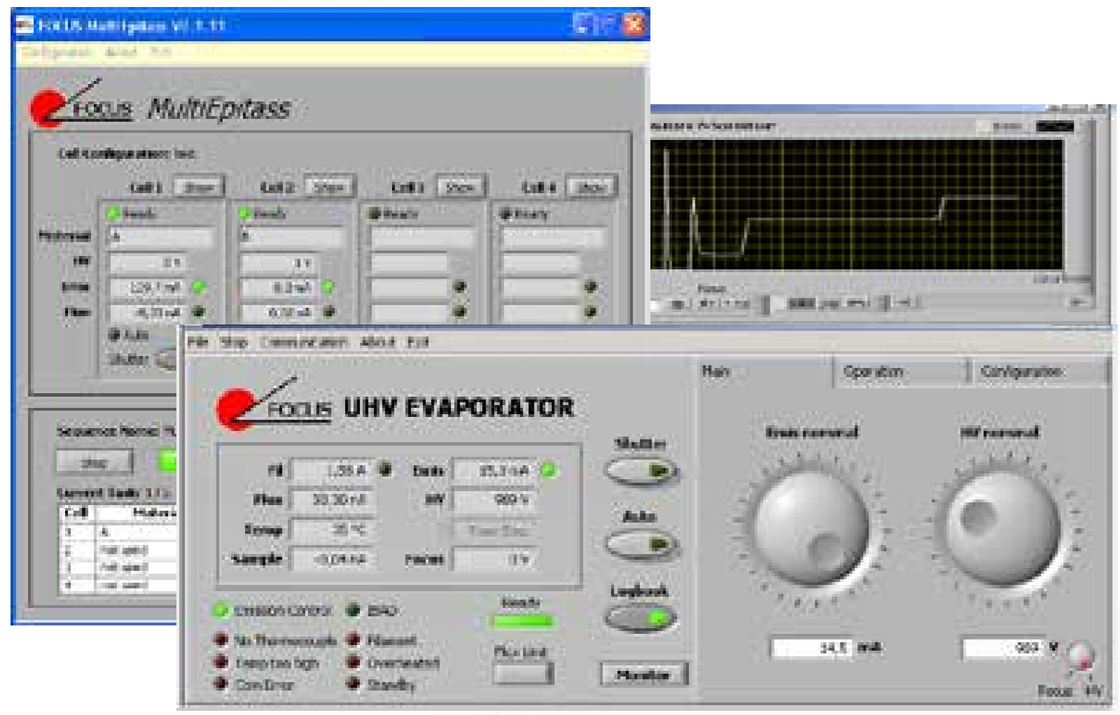

All microprocessor controlled EVC-series power supplies in combination with the Epitass® software make the operation of all EFM-type UHV evaporators very convenient and safe.

They can control the power of the EFM-H up to 100 W power which already provides maximum dissociation of molecular hydrogen.

For operation of the EFM-H only (not the evaporator range) there is a basic version of the electronics available: EVC 100L

All the other features of the EVC-series please refer to the EFM 3 and EFM 4 product information.

Ion Suppression

The option Ion suppression adds an electrode to the EFM - H: EFM - Hs, where s stands for suppression. A part of the dissociated hydrogen beam produced in the EFM- H is ionised by the electron bombardment during heating.

As the dissociation tube is on high voltage with respect to the grounded sample the remaining ions may create defects in the substrate surface and deposit energy.

To generate a 100 % neutral beam an additional voltage is applied at the suppressor electrode of the EFM - Hs. The additional voltage is supplied by the power supply EVC 300s-2 or EVC 100s.

Specifications

>3000 °C

Water

± 15° to ± 6° (approx.)

Up to 250 °C

DN 40 CF

142 mm

EVC 100L, EVC 100(s), EVC 300(s)-2, EVC 300i

Shutter

Special length

Ion suppression

Pumping bypass

For full specifications and more information about product options, please do not hesitate to contact your local sales representative. Find the contact details here: Contact Us